The deployment of machine control systems in the most challenging environments

The performance of Global Navigation Satellite System (GNSS) receivers does vary from one machine to another, which is critical to the performance of the guidance system in the face of challenges. When GNSS fails, such as due to poor satellite visibility or interference, each idle machine can cost an operator approximately $1,000/day. Therefore, having a high-quality GNSS receiver that works even in harsh environments is critical.

Septentrio is a reputed company in the field of GNSS receivers and is known for its innovative technology and high quality products. The GNSS receivers offered by the company are used worldwide for their reliability and accuracy, especially in demanding applications.Septentrio's AsteRx multi-frequency heading GNSS receiver is a leader in its product line, with built-in LOCK+ technology, which allows tracking of GNSS satellites, even under severe vibration or mechanical shocks, thus enabling machine guidance in harsh conditions. Enabling machine guidance.

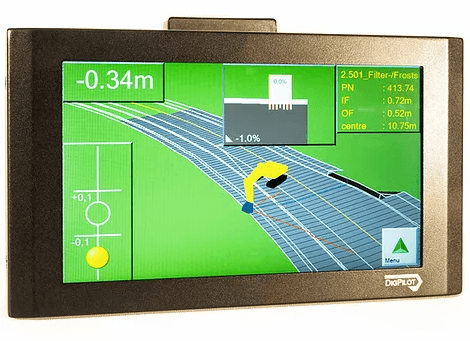

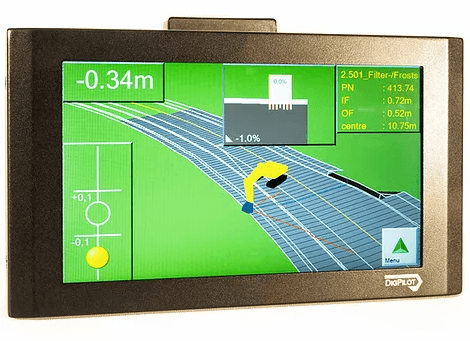

Norwegian machine control system manufacturer Gundersen & Løken AS uses Septentrio's AsteRx multi-frequency homing GNSS receiver in its 3D guidance system products, and the receiver's high performance makes it a key component in the DigPilot system, a 3D guidance system supplied by Gundersen & Løken AS. DigPilot is a 3D guidance system provided by Gundersen & Løken AS that utilises Septentrio's GNSS technology to improve the accuracy and efficiency of excavation and construction operations.

DigPilot's customer, Volda Maskin, has used DigPilot's 3D guidance system for excavation work in challenging environments, such as the refurbishment of the E39 European highway on the Norwegian west coast, where they were able to continue their work despite the fact that the construction site was next to a solid 15 metre-high rock wall, which partially blocked the view of the sky and reflected the GNSS satellite signals, causing multipath interference. They were able to continue working and complete the project on time and within budget.

The working principle of the GNSS receiver is based on the measurement of pseudo-distance and carrier phase. By receiving and processing the satellite signals, the distance and angle information between the receiver and the satellite is calculated, and then the receiver's position and speed are determined. The AsteRx-m3 CLAS, on the other hand, is a multi-frequency GNSS receiver with top-level positioning performance that can provide heading and pitch or heading and roll information in dual-antenna mode.

Septentrio's GNSS receivers incorporate a number of advanced technologies to ensure high quality positioning in a variety of environments. Among them, LOCK+ technology maintains signal tracking under severe vibration or shock, while IONO+ technology provides protection against ionospheric interference. In addition, Septentrio's GNSS receivers are highly resistant to interference and can maintain accurate positioning in environments with interfering signals.

Overall, the performance of GNSS receivers is critical to ensure accurate guidance of machines in harsh environments, and Septentrio offers high-quality GNSS receivers and advanced technologies such as LOCK+ and IONO+ that can significantly improve the reliability and efficiency of the system in the face of challenges.

Overall, the performance of GNSS receivers is critical to ensure accurate guidance of machines in harsh environments, and Septentrio offers high-quality GNSS receivers and advanced technologies such as LOCK+ and IONO+ that can significantly improve the reliability and efficiency of the system in the face of challenges.